Analog Curvature

Smart Surfaces

Cambridge, MA

MIT, Geometric Disciplines

Instructor: J. Jih

Can we express curvature through embedded material intelligence?

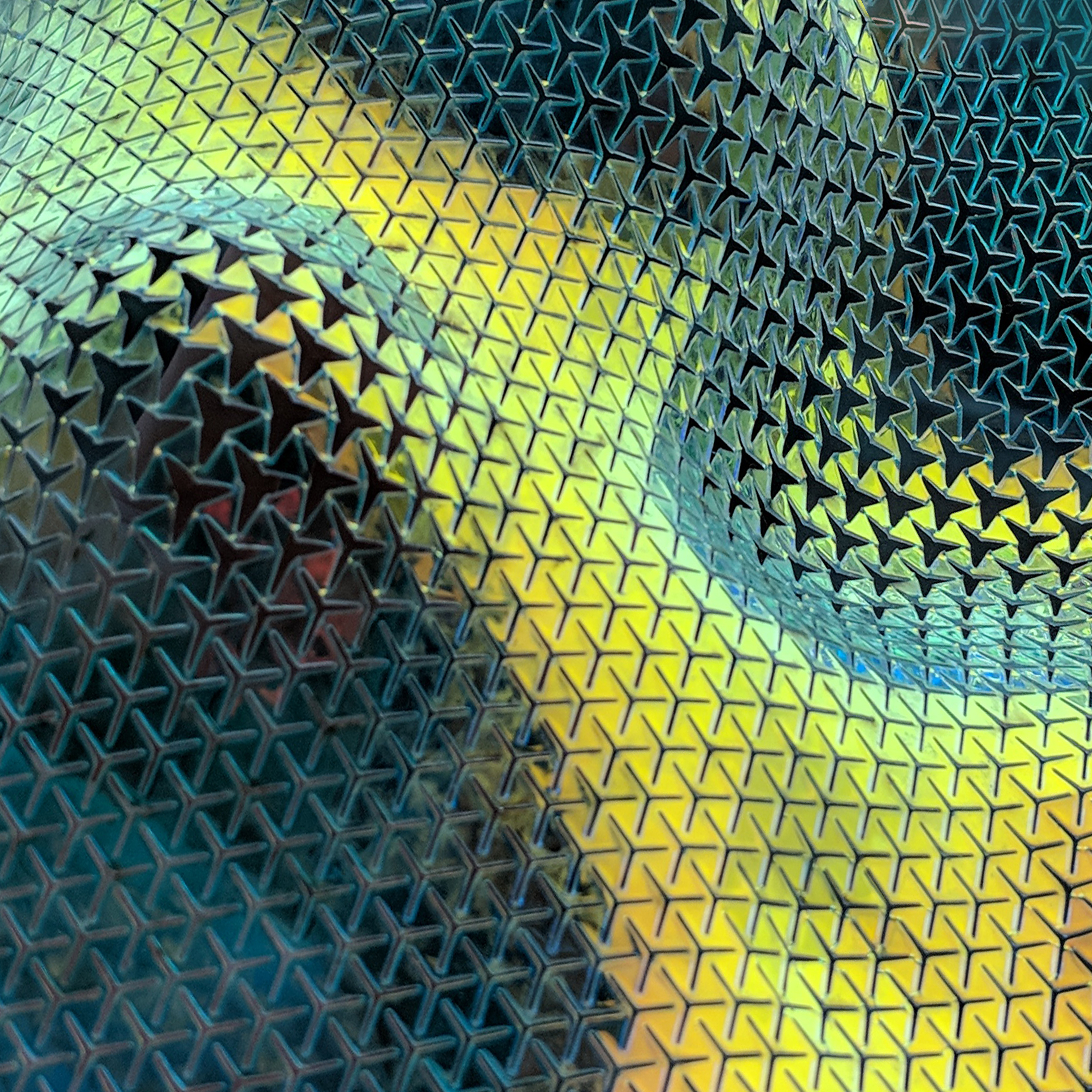

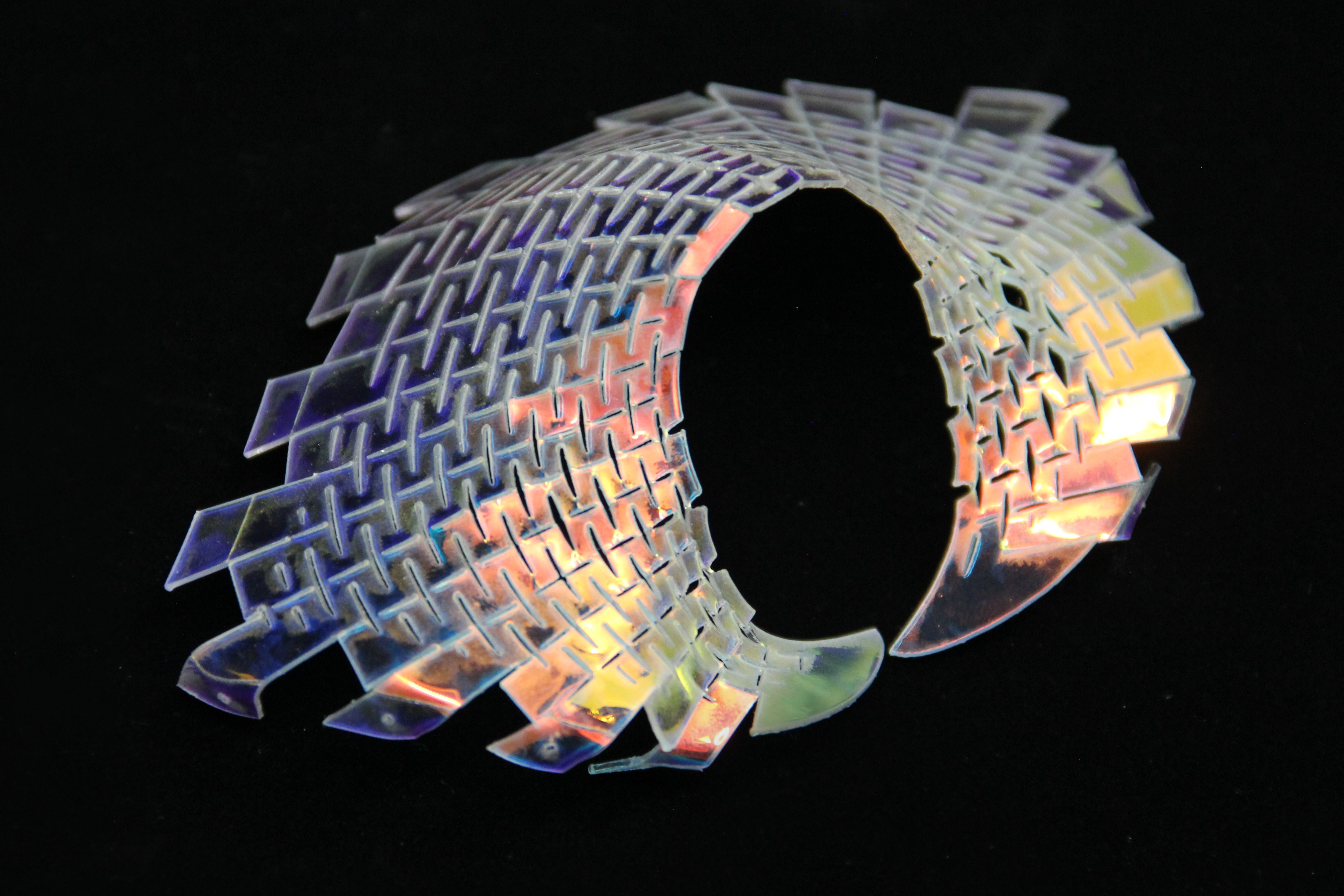

Auxetic patterning allows for precise forming of doubly curved surfaces.

Dichroic film interacts differently with light relative to viewing angle.

In tandem, these operations allow planar material to become a measure of surface curvature for any given point along a three-dimensional surface.

Material Detail: Dichroic Film + Auxetic Pattern

Material Study

Using test swatches to understand wavelength separation behavior.

Dichroic film PETG cladding is incrementally formed against the spaceframe and pinned into the edges of the rigid profiles. This mechanical deformation opens the auxetic pattern, creating variation in surface curvature within the assembly.

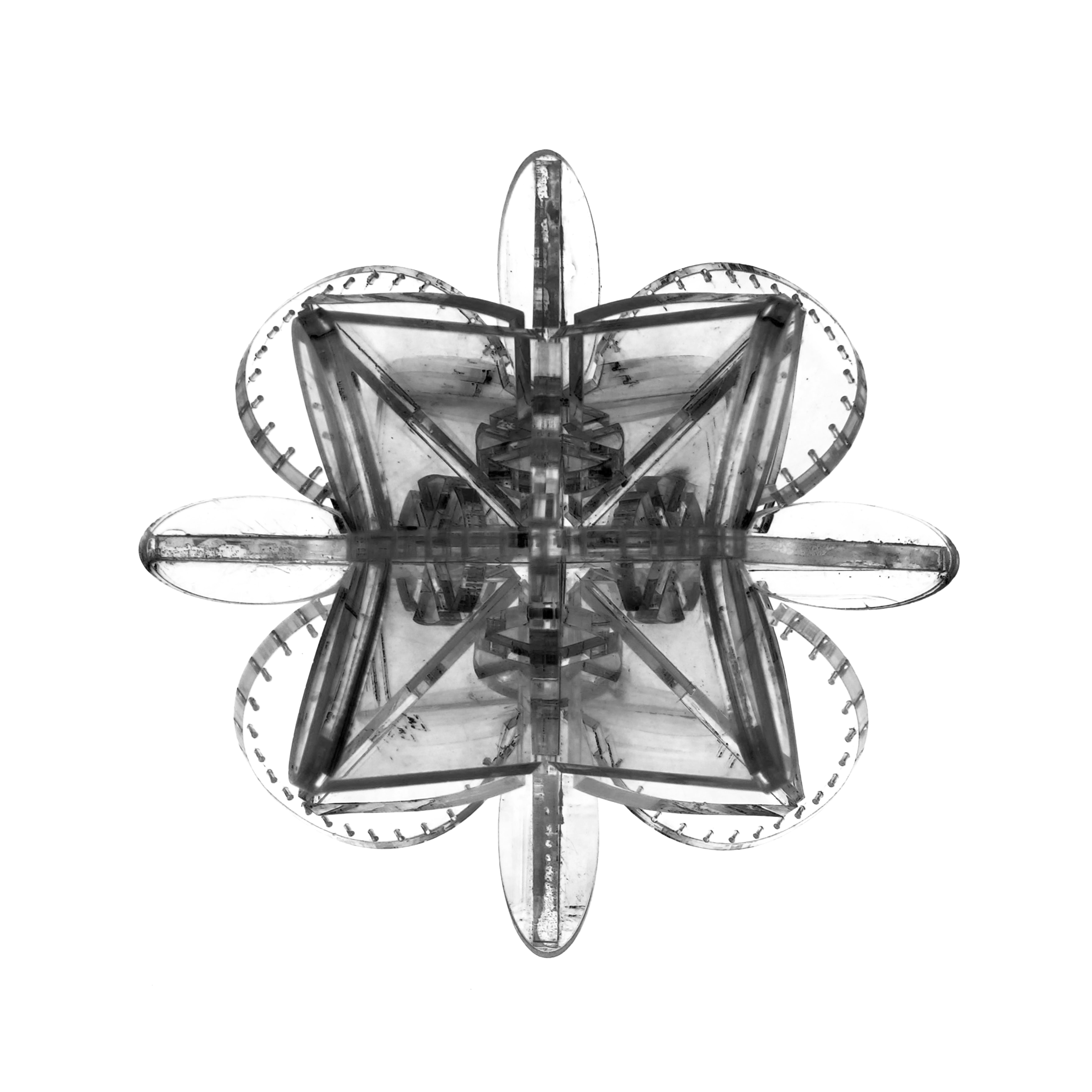

Assembly Axonometric

Assembly Axonometric

The complex angles required to support surface panels are resolved with simple lasercut profiles. Each piece of the 36-way joint can be friction fit together, only locking into place once all of the segments come together.

Incrementally Formed Panel Detail

Incrementally Formed Panel Detail

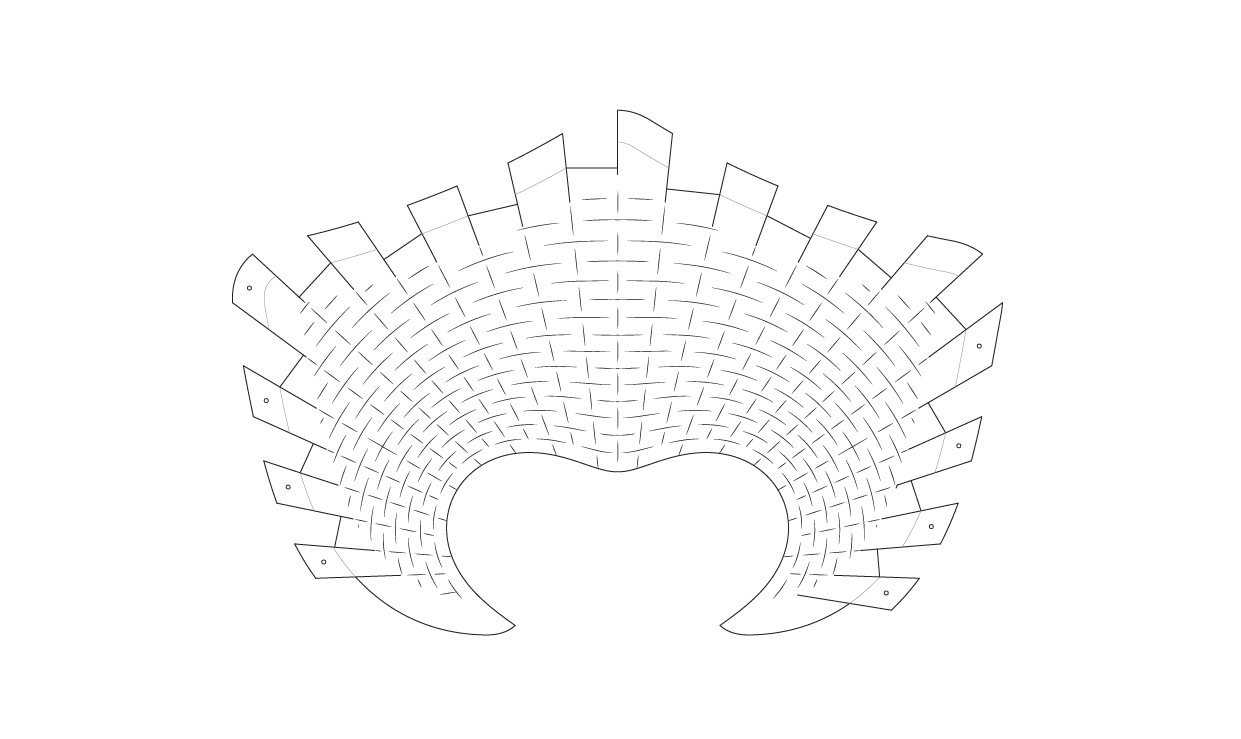

Pattern Geometry; 2D Panel

The auxetic cut pattern is callibrated according to the isocurvature of the intended surface. When stretched on the spaceframe, the cuts open and allow the sheet to deform into the 3D surface.

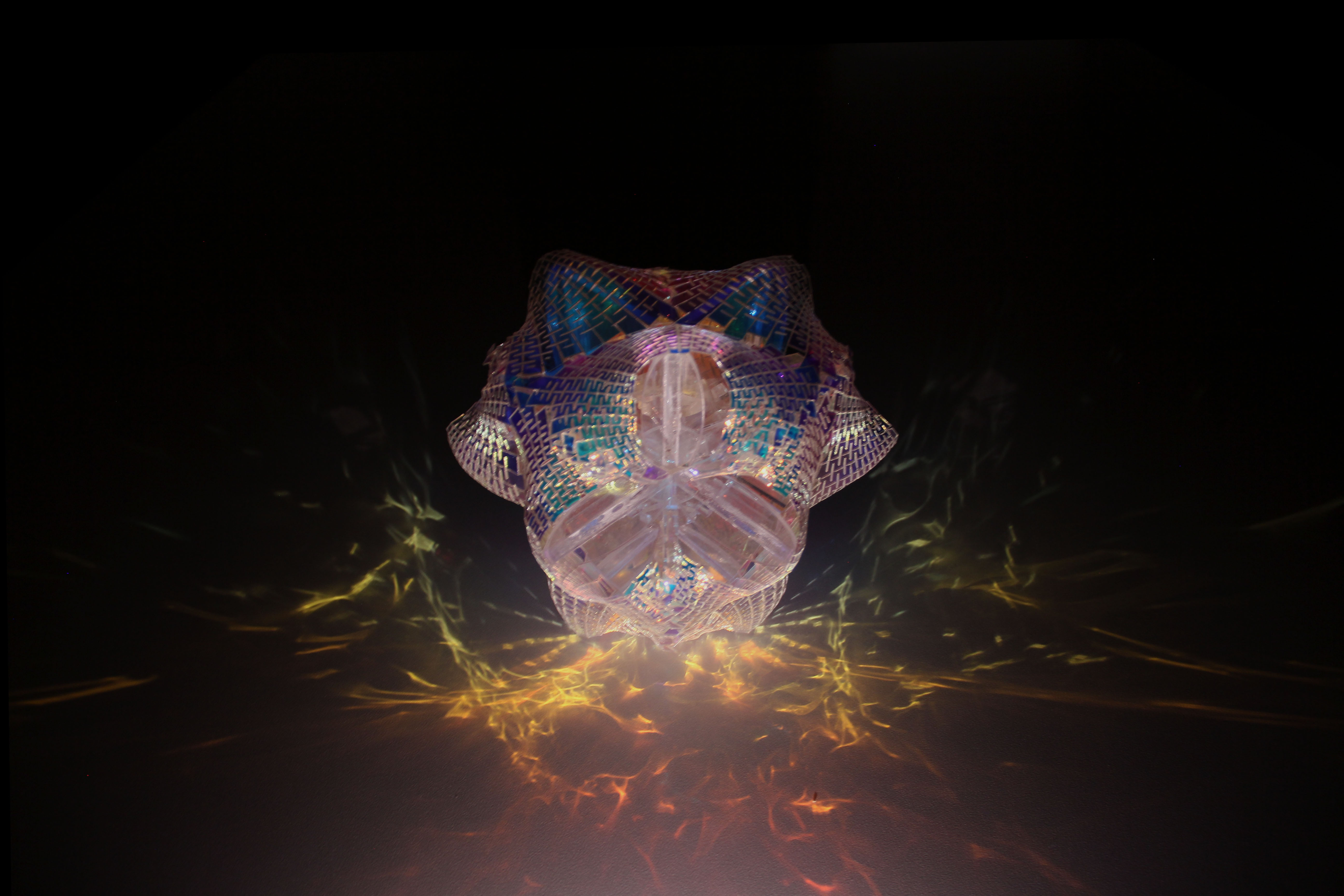

Diffuse Light

Emitted Light

Reflected Light